I. Components and Their Combinations

1.1 Basic Components

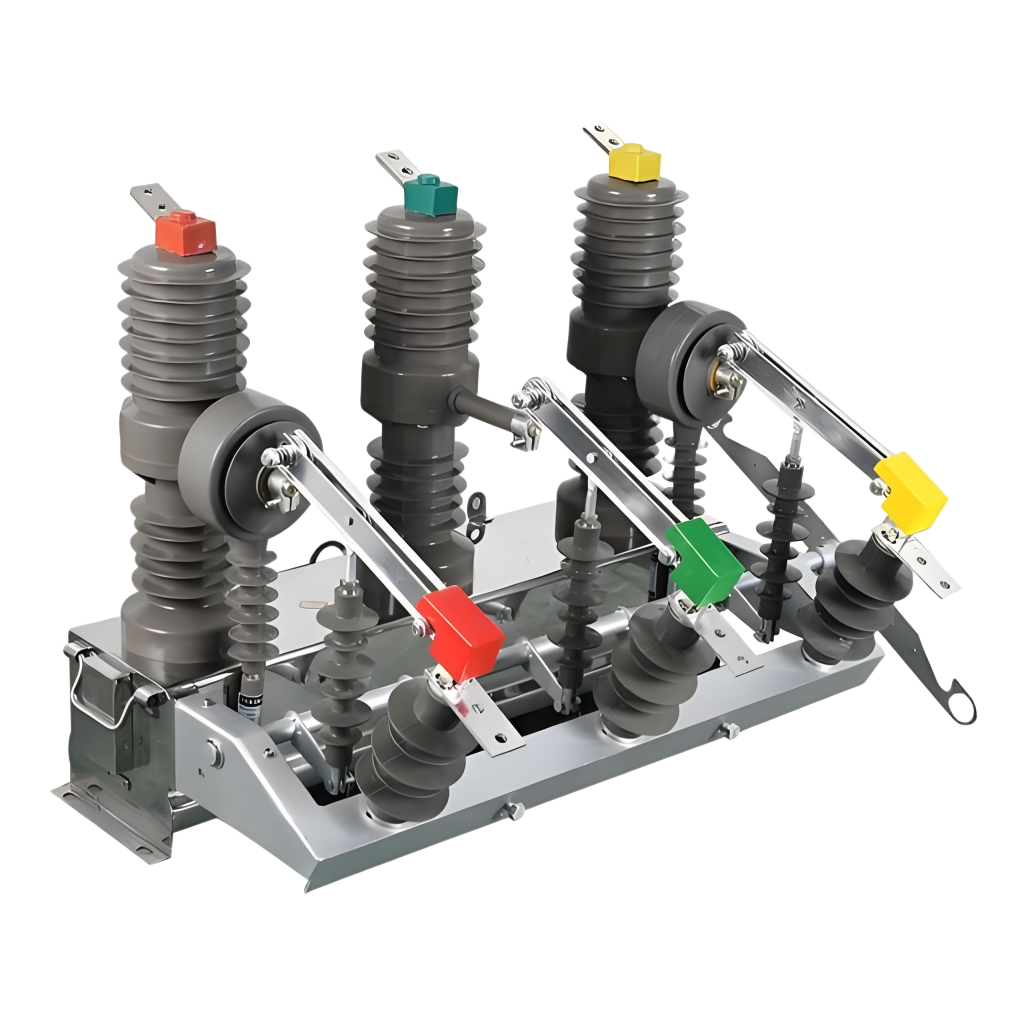

High-voltage systems integrate specialized components to ensure reliable power distribution, protection, and control. Key components include:

- Circuit Breakers: Control normal load currents and automatically interrupt fault currents (e.g., short circuits). Key Feature: Can reset after fault clearance, unlike fuses.

- Disconnecting Switches: Isolate circuits to enable safe maintenance or repairs. Key Feature: Designed for de-energized operations; cannot interrupt load/fault currents.

- Grounding Switches: Ensure safe grounding of equipment during servicing to protect personnel from residual charge.

- Reclosers: Automate reclosing after transient faults (e.g., lightning-induced flashovers) to restore service without manual intervention.

- Segmenters: Automatically isolate faulty sections of a network to prevent cascading failures.

- Load Switches: Connect/disconnect electrical loads under normal conditions (no fault-interrupting capability).

- Contactors: Remotely control circuit connectivity (e.g., motor starters, remote switching).

- Fuses: Sacrificial overcurrent protection devices that melt during overloads/short circuits to isolate faults.

1.2 Component Combinations

Components are paired to address complex requirements:

- Load Switch–Fuse Combination: Combines load-breaking capability with overcurrent protection. Ideal for distribution networks where frequent manual intervention is impractical.

- Contactor-Fuse (F-C) Combo: Merges contactor-based control with fuse protection for motors or transformers. Protects against overloads while enabling remote operation.

- Isolated Load Switches: Integrates isolation and load-breaking functions, reducing the need for separate disconnectors.

- Fuse-Type Switches: Prioritizes fuse protection in compact designs, often used in low-to-medium voltage applications.

- Open-Type Assembly: Customizable configurations tailored to specific project needs (e.g., industrial plants, substations).

II. High-Voltage Complete Sets of Equipment

2.1 High-Voltage Switchgear

Definition: Manufacturer-assembled units integrating circuit breakers, disconnectors, transformers, protection/control systems, and instrumentation. Modular designs allow scalable expansion.

Structure Types:

- Metal-enclosed: Compact, weatherproof cabinets for indoor/outdoor use.

- Armored: Reinforced casings for harsh environments.

- Box-type: Encapsulated designs for dust/moisture resistance.

- SF₆-insulated: Uses sulfur hexafluoride gas for compact, maintenance-free insulation.

Installation Modes:

- Fixed or trolley-mounted circuit breakers for flexibility.

- Indoor/outdoor placement depending on environmental ratings.

Cabinet Designs: Open (accessible) or closed (sealed) architectures.

Safety Interlocks:

- “Five-Proof” System: Prevents unintended circuit breaker operation, load-side disconnector actuation under load, grounding switch closure under live conditions, energizing circuits while grounding is engaged, and unauthorized access to live compartments.

- Mechanism: Mechanical/electromagnetic interlocks enforce operational safety.

2.2 High-Voltage Power Distribution Equipment

Components: Cabinets, switchgear, protective relays, meters, busbars, conductors, insulators.

Functions:

- Switching: Controls circuit connectivity (e.g., isolating faulty lines).

- Protection/Measurement: Relays detect faults (overcurrent, earth leakage); meters monitor voltage/current.

- Energy Routing: Busbars and conductors distribute power efficiently.

Applications: Core to power plants and substations for grid control and equipment safeguarding.

III. Other Complete Sets of Equipment

3.1 SF₆ Fully Enclosed Composite Apparatus

Components: Circuit breakers, disconnectors, grounding switches, CTs/VTs, surge arresters, busbars, connectors, terminals.

Key Features:

- SF₆ Gas: Pressurized sulfur hexafluoride provides insulation and arc extinction. Stable under normal conditions, rapidly quenches fault arcs.

- Advantages: Compact footprint, low maintenance (no oil/grease), resistant to environmental contaminants.

Use Cases:

- 35kV+ substations, urban grids (space-constrained areas), new/retrofitted stations.

3.2 High-Low Voltage Prefabricated Substation

Design: Integrates high-voltage sections, transformers, and low-voltage components in a single metal casing.

Functions:

- Power conversion (step-down/step-up) via transformers.

- Unified energy distribution for indoor/outdoor deployment.

Benefits: Plug-and-play functionality, reduced installation time, and enhanced reliability.

Summary of Applications

- High-Voltage Switchgear: Substations, industrial power hubs.

- SF₆ Apparatus: Urban areas, compact substations, pollution-prone environments.

- Prefabricated Substations: Rapid-deployment scenarios (e.g., emergency power, remote sites).